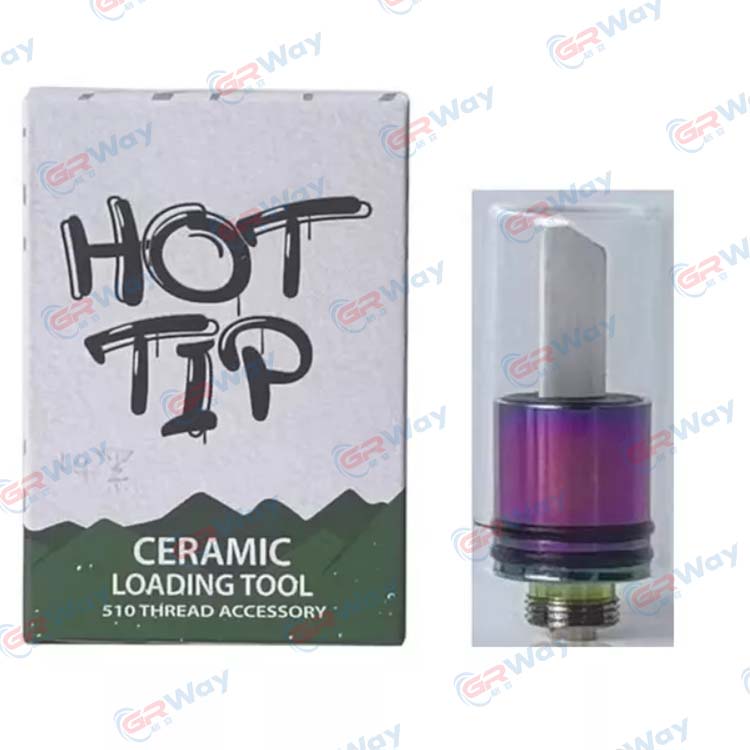

A1321 Soldering Ceramic Heating Element

Send Inquiry

PDF DownLoad

Process of A1321 Ceramic soldering Heating Element

A1321 Soldering Ceramic Heating Element GRWAY® produced by implementing ceramic lamination processes. Due to the compactness, high power and rapid heating speed. Ceramic Heating element can provide higher reliability than ever before.

Main materials of A1321 Ceramic soldering Heating Element

Heater body: white alumina ceramic, and the content of alumina is no less than 95%.

Ni-wires: N6 Ni-wires with0.6mmdiameter.

Brazing material: Ag72Cu28

Material Properties of A1321 Ceramic soldering Heating Element

|

Item |

Inspection Condition |

Unit |

Standard |

|

Color |

|

|

White |

|

Density |

|

g/cm3 |

3.7 |

|

Water absorption |

|

% |

0 |

|

Average grain size |

|

μm |

3~5 |

|

Hardness

|

Load 4.9N 4.9N |

GPa |

≥15 |

|

Flexural strength |

|

MPa |

≥274 |

|

Linear expansion coefficient |

20~500℃ |

1×10-6mm/℃ |

6.5~7.5 |

|

20~800℃ |

6.5~8.0 |

||

|

Thermal conductivity |

20℃ |

W/(m·K) |

≥20.9 |

|

Specific heat |

|

kJ/(kg·K) |

≥0.8 |

|

Insulation strength |

|

KV/mm |

≥12 |

|

Volume resistivity |

20℃ |

Ohm.cm |

≥1014 |

|

300℃ |

≥1011 |

||

|

500℃ |

≥109 |

||

|

Permittivity |

1MHz |

|

9~10 |

|

Dielectric loss tangent |

1MHz |

|

≤3×10-4 |

|

Surface roughness |

|

μm |

0.3~0.8 |

Parameter of A1321 Ceramic Soldering Heating Element

|

Heater Name |

A1321 Ceramic Heating Element |

|

Working Voltage |

24V |

|

Working Power |

50W+/-10% |

|

Dimension |

Length 60mm* diameter 3.8mm |

|

Heating Resistance |

3 ohm+/-10% |

|

Sensor Resistance |

50ohm+/-10% |

|

Application |

HAKKO 936 soldering Station |

|

Leads |

Nickel wires |

|

Working Temperature |

400~500℃ |

|

Insulation Sleeve |

Accordingly |

Detailed dimension of A1321 Ceramic Soldering Heating Element