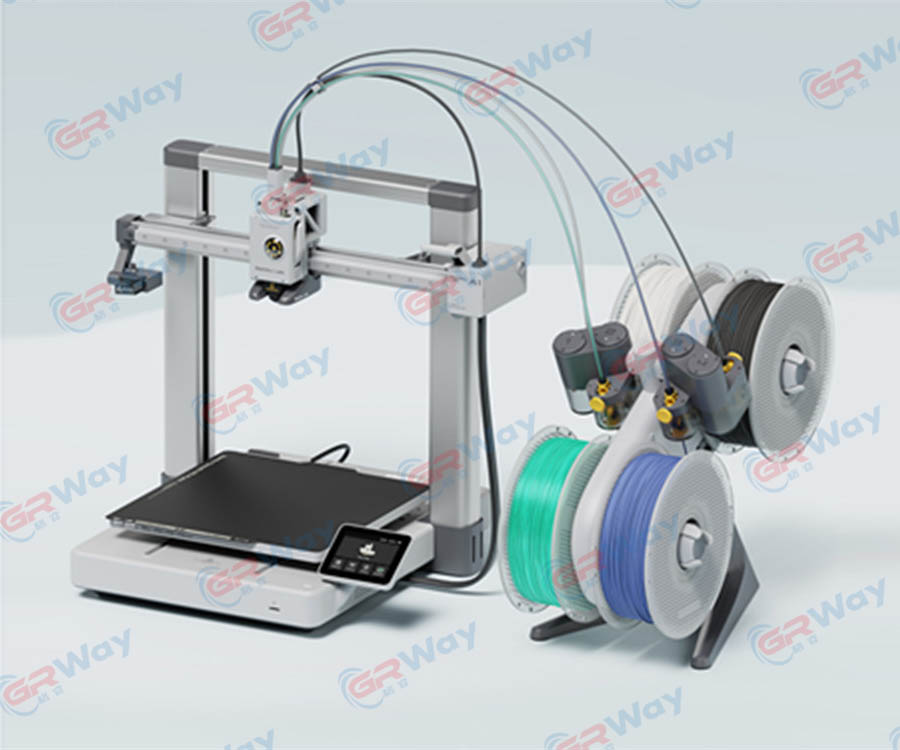

Hot End Ceramic Heating Plate for Bambu 3D Printers

Send Inquiry

GREENWAY’s high quality hot end ceramic heating plate for bambu 3D printers, particularly MCH (Metallized Ceramic Heater) are used in 3D printers as alternatives to traditional heating elements for their efficiency, smaller size, uniform heating, and precise temperature control. They are commonly found in hotends to melt filament and on heated build plates to prevent warping and improve first-layer adhesion.

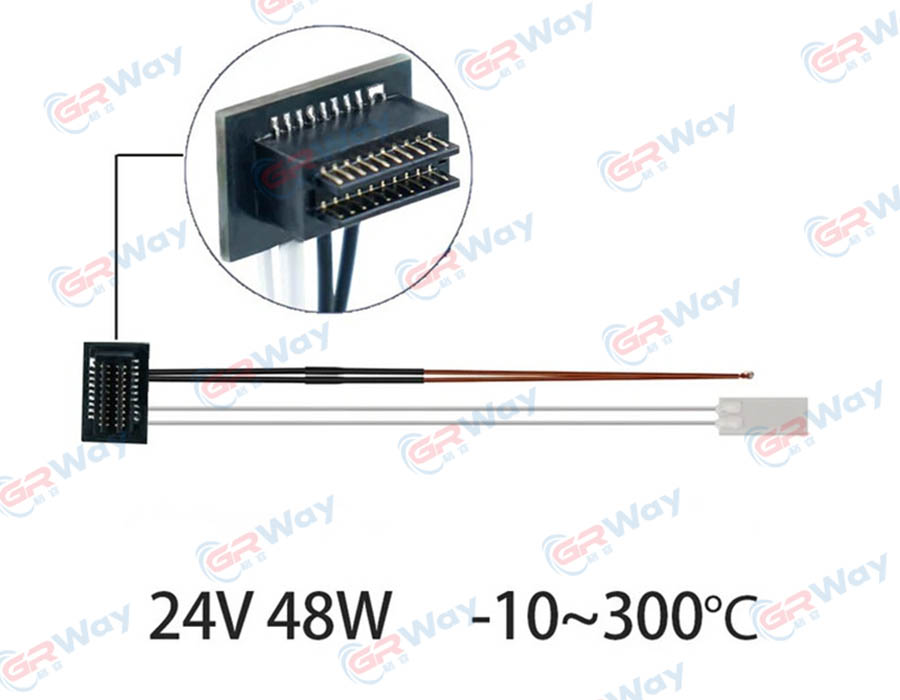

Bambu 3D Printer Heater Plate Parameters:

|

Working voltage |

24V |

|

Heating power |

48W |

|

Length*width(mm) |

15*7mm |

|

Lead length |

105 mm or accordingly |

|

Crimp |

Accordingly ( Have or Not) |

|

Sleeve |

PTFE or not |

|

Compatible filaments |

PLA, ABS,PETG,TPU,PP,PC,Nylon ect. |

|

Working temperature |

300℃high temperature resistance |

This 48W ceramic heater element improves heating efficiency,more uniform heating and faster heat transfer.

Advantages of ceramic heaters in 3D printers:

Rapid and uniform heating: Ceramic heaters in 3D printers can reach operating temperatures significantly faster than metal-cased cartridge heaters. 3 seconds till 200 ℃ and 5 seconds to 300 ℃.

More safety: This material automatically increases its electrical resistance as it gets hotter, which naturally limits its maximum temperature and prevents thermal runaway.

Compact and lightweight: Ceramic heating cores are smaller and lighter than traditional heating tubes. This allows for a more compact and lightweight hotend design, which can lead to faster and more accurate printing, especially with input shaping and high-speed printing.

Increased durability: Ceramic heating elements are resistant to thermal shock and high temperatures, making them robust and reliable for thousands of heating cycles.