Ceramic Pellet Igniter 300W

Send Inquiry

PDF DownLoad

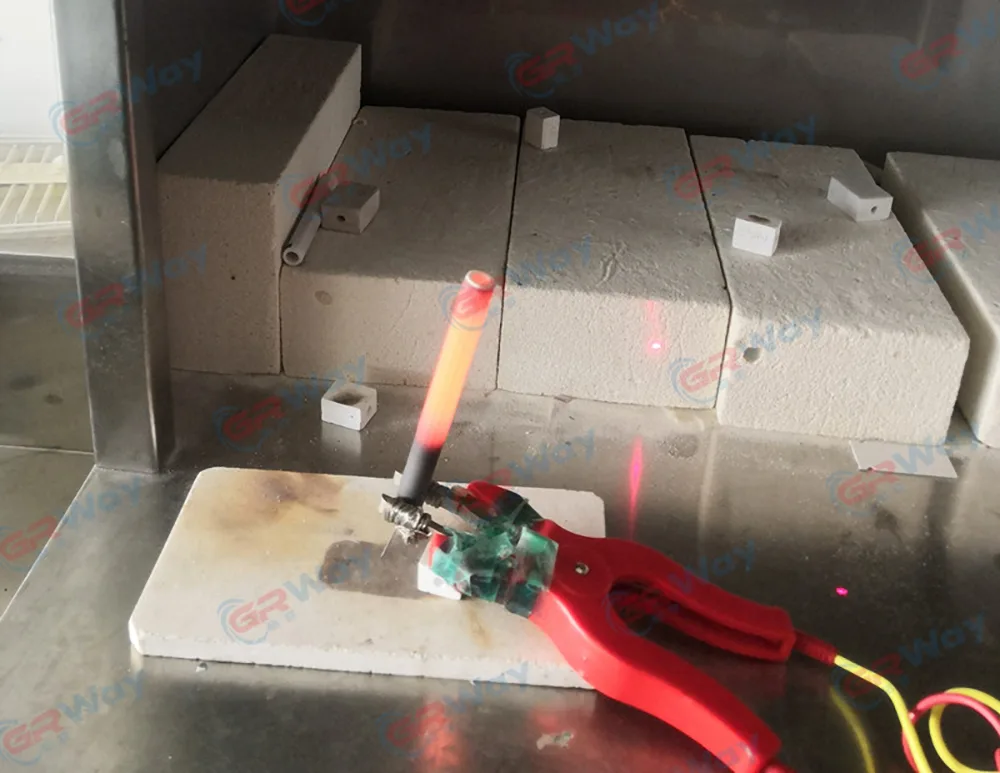

GREENWAY’S Ceramic Pellet Igniter 300W produced by HTCC(high temperature co-fire) processes. Main material is 92~96% aluminum ceramic.The metal heating resistance slurry is printed onto the ceramic sheet,laminated together and co-fired under 1500-1600℃.

Greenway's R&D team meticulously designed this product to achieve an ultra-high surface temperature that instantly ignites combustibles like gas and fuel, shortening equipment startup time and reducing fuel waste. Its 300W power design ensures explosive heating while also managing energy consumption and avoiding excessive power consumption.

Our Ceramic lighter take the advantages of fast ignition speed (30 seconds to 500 degrees, 60 seconds to 800 degrees), anti-carbon deposition, long life (continuous operation over 5000 hours), etc.. Adapt to various pellet burner equipment.

Product general information

|

Brand |

GREEN WAY |

|

Material |

95% aluminum ceramic |

|

Certificates |

Rohs/Reach/CE |

|

Working Temperature |

850℃~1050℃ |

|

Heater dimension |

106mm long*OD11.5mm |

|

Flange |

Ceramic flange or copper thread or others |

|

Ignition time |

60~90 seconds |

|

Wire type |

Silicon cable/fiber glass cable or accordingly |

|

Wire length |

35cm or accordingly |

|

Customization |

Logo/dimension ect. welcome |

Product Features

It is a new type of high efficient heating elements, which can save more than 20%-30% power effect compare to PTC ceramic heaters.

1.High power density, excellent thermal efficiency

2.Rapid heating, non-hot spot temperature distribution

3.High temperature, small size, light weight

4.Excellent insulation (the leakage current is < 0.5 mA under voltage 4500V/1S testing with no breakdown)

5.High reliability, stable resistance, no electric noise

6.Good chemical resistance

7.Our Certificates:ROHS/REACH AND CE

Application

Wood pellet stove

Wood pellet boiler

Wood pellet burner

Wood chips burner

Straw burner

Other biomass burner

Handling and notice of using

1.Don’t give the ceramic heater impact like falling down to the ground or strike it by hammer forcefully.

2.Using ceramic heater at rating voltage.

High voltage may cause the damage of ceramic heater.

3.Temperature control device should be used on ceramic heater

And the surface temperature of ceramic heater should no more than 800℃,since the temperature is closely related to its working life.