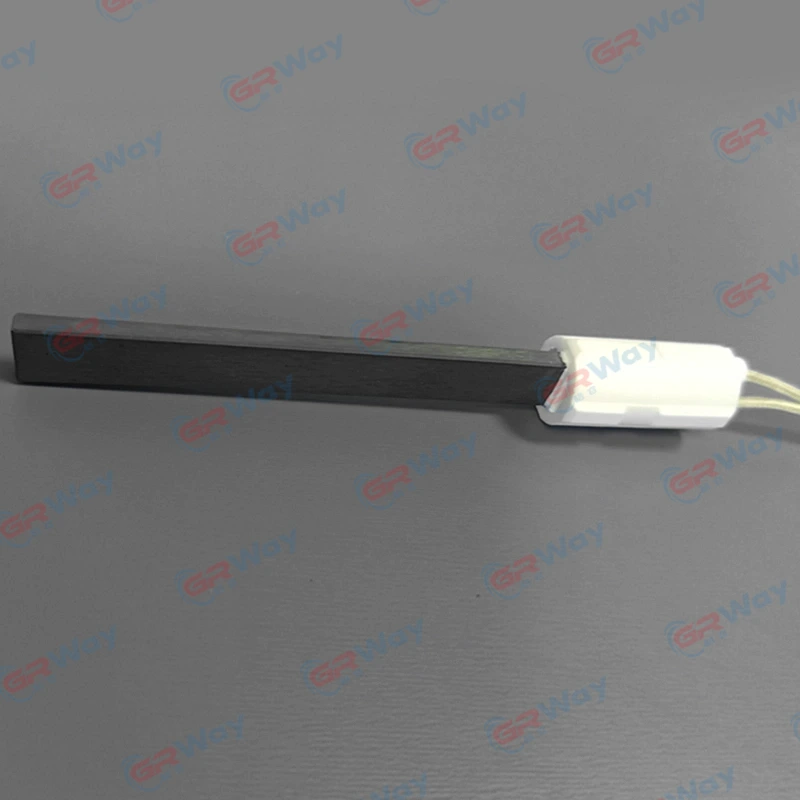

High Temperature Sic Heating Element for Solid Fuel Boilers

Send Inquiry

GREENWAY is a manufacturer of kinds micro high temperature heating elements such as aluminum ceramic,silicon nitride and ALN nitride ect. Among these, Silicon nitride heating element is with silicon nitride (Si₃N₄) as the main material. Sic Heating Elements has significant advantages in the field of high-temperature heating.

Our new product High Temperature Sic Heating Element for Solid Fuel Boilers has been developed by a professional team and laboratory, and tested on the production line. It has many advantages of contemporary micro-fast heating elements. Pellet Burner Heater has always been a convenient heater for us at home or traveling. Choose GREENWAY and let us add luster to your life!

Product Specifications

|

NO |

Working voltage(V) |

POWER(W) |

Working temperature(℃) |

Dimension/Length*width*thickness(mm) |

|

1 |

24V |

200W |

1015℃ |

95*10*3.0 |

|

2 |

110V |

300W |

1045℃ |

106*11*5.0 |

|

3 |

220V |

300W |

1030℃ |

121*11*5.0 |

|

4 |

220V |

400W |

1080℃ |

122*11*5.0 |

|

5 |

220V |

650W |

1140℃ |

132*17*5.0 |

Product Advantages

1.Excellent high temperature resistance

Strong high-temperature stability: The melting point of silicon nitride is as high as 1900℃ or above. The heating element can work stably for a long time in a high-temperature environment of 1300-1600℃, far exceeding traditional metal heating elements (such as nickel-chromium alloy, up to about 1200℃) and some ceramic heating elements (such as alumina, up to about 1600℃ but poor stability).

2.Outstanding thermal shock resistance

3.Strong chemical stability

4.High mechanical strength

5.Long service life

GREENWAY’s Solid Fuel Boilers Ignition is usually longer than that of metal or ordinary ceramic heating elements, especially under high temperature conditions above 1400℃, the advantages are more obvious, which can reduce the replacement frequency and maintenance costs.

![]()

Product Application

Suitable for high temperature fields: such as high temperature sintering furnaces, pellet burners, pellet stoves,pellet boilers,solid fuel boilers,atmosphere furnaces, crystal growth furnaces, industrial kilns, etc.